QUARTZ

Critical industrial mineral, valued for its high silica content, low impurities, and versatility. Mineastra supplies Quartz in Lumps, Grits, Powder, and HPQ (High-Purity Quartz), serving glass, ceramics, electronics, foundries, engineered stone, and construction industries. With partner mine capacity of 8,000–10,000 MT/month, Mineastra delivers consistent bulk supply of Quartz Lumps, Grits, and Powder for glass, ceramics, and industrial buyers.

EXTENDED PRODUCT DESCRIPTION

APPLICATION IMAGES

EXTENDED SPECS

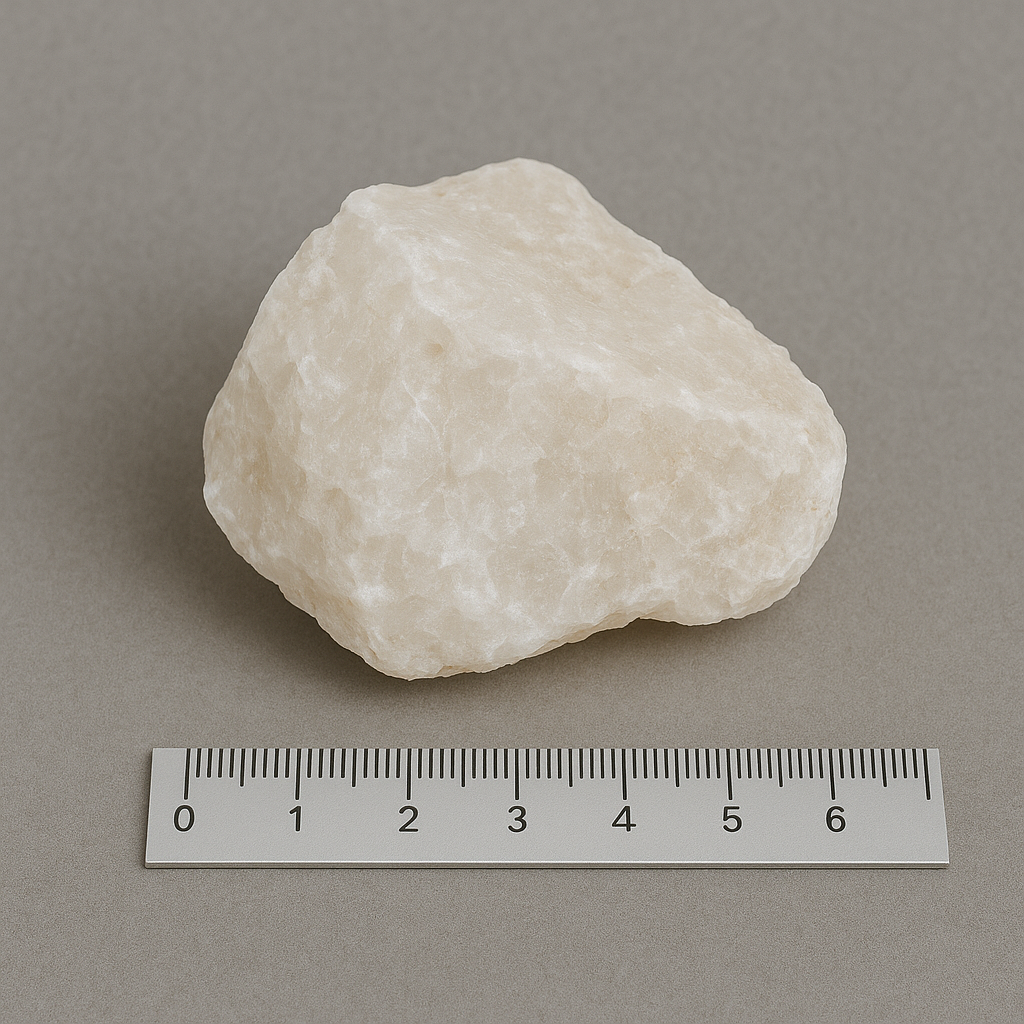

RAW STONES

QUARTZ

LUMPS

White (Snow-White Grade)

Semi-white / off-white

Snow White Quartz Lumps

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina): ≤ 0.3%

Fe₂O₃ (Iron Oxide): ≤ 0.02%

Moisture: < 0.1%

Whiteness: 97%

Color / Appearance: Brilliant, pure white

Applications:

High-grade glass manufacturing

Optical glass

Solar glass

Premium engineered stone (slabs & countertops)

High-purity ceramics

Industrial

Industrial Grade Quartz Lumps

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture: < 0.5%

Whiteness: 85%

Color / Appearance: White-grey, brownish patches

Applications:

Bulk cement production

Ferro-silicon alloying

Construction fillers

Refractory bricks

Chemical industries

Milky White

Milky White Quartz Lumps

SiO₂ (Silica): 98.5-99.5%

Al₂O₃ (Alumina): 0.3% – 0.7%

Fe₂O₃ (Iron Oxide): 0.03-0.05%

Moisture < 0.2%

Whiteness: 90% – 94%

Color / Appearance: Bright milky white, uniform, minimal patches

Applications:

Countertops & engineered stone (quartz surfaces)

Glass manufacturing (clear/colored glass)

High-end ceramics & sanitaryware

Foundry applications

Physical Specifications

Size Fractions (Screened & Graded): 25 – 50 mm, 50 – 100 mm, 100 – 150 mm, 150 – 250 mm, 250 mm

Density / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Manual handpicking, optical sorting, or mechanized screening

Impurity Control:

Low Fe₂O₃ for glass & ceramics

Strict selection for engineered stone

Properties: Lusture, Hardness, Fracture, Density, Melting point,

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

Off White / Cream Quartz Lumps

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92%

Color / Appearance: Slight cream / off-white

Applications:

Regular glass manufacturing

Sanitaryware ceramics

Foundries (moulding sand)

Paints & coatings fillers

Refractories

Snow-white Grits

Semi White Quartz Grits

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92% (slight cream)

Color / Appearance: Off-white / cream shade

Applications:

Container & regular glass

Sanitaryware ceramics

Refractories

Foundries (moulding sand)

Paints & coatings fillers

Physical Specifications

Size Fractions (Screened & Graded): 0.1 – 0.3 mm, 0.3 – 0.6 mm, 0.6 – 1.2 mm, 1.2 – 2.5 mm, 2.5 – 4.0 mm, 4.0 – 6.0 mm, 6.0 – 10 mm

Density / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Multi-stage crushing, sieving, and optional optical sorting for premium grades

Impurity Control:

Snow White: Ultra-low Fe₂O₃ (<0.02%) for solar, optical glass, engineered stone

Semi White: Balanced Fe₂O₃ levels, strict sizing for sanitaryware/ceramics

Industrial Mixed: Higher tolerance impurities, optimized for cement & metallurgical industries

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

GRITS

Industrial Grits

Industrial Quartz Grits

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture < 0.5%

Whiteness: 80 – 85% (greyish)

Color / Appearance: White-grey, mixed tone powder

Applications

Bulk cement production

Construction fillers

Ferro-silicon alloying

Refractory bricks

Chemical industries

Semi-white Grits

Snow White Quartz Grits

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina): ≤ 0.3%

Fe₂O₃ (Iron Oxide): ≤ 0.02%

Moisture: < 0.1%

Whiteness: 97%

Color / Appearance: Brilliant, pure white

Applications:

High-grade glass manufacturing

Optical glass

Solar glass

Premium engineered stone (slabs & countertops)

High-purity ceramics

POWDER

Semi White Quartz Powder

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92% (slight cream)

Color / Appearance: Off-white / cream shade

Applications

Container & regular glass

Sanitaryware ceramics

Refractories

Foundries (moulding sand)

Paints & coatings fillers

MICRONISED

Snow White Quartz Powder

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina) ≤ 0.3%

Fe₂O₃ (Iron Oxide) ≤ 0.02%

Moisture < 0.1%

Whiteness: 96 – 97% (ultra white)

Color / Appearance: Pure brilliant white, fine powder

Applications

Engineered stone & quartz slabs

Optical & solar glass

High-purity ceramics

Paints & coatings fillers

Plastics & polymers

Industrial Quartz Powder

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture < 0.5%

Whiteness: 80-85% (greyish)

Color / Appearance: White-grey, mixed tone powder

Applications

Bulk cement production

Construction fillers

Ferro-silicon alloying

Refractory bricks

Chemical industries

Physical Specifications

Particle Sizes (Micronized):

D50 = 45 µm, 38 µm, 25 µm, 20 µm, 10 µm, 5 µmDensity / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Multi-stage crushing → ball mill/pulverizing → micronized sieving → air classification

Impurity Control:

Snow White Powder: Ultra-low Fe₂O₃ for engineered stone, solar glass, optical-grade uses

Semi White Powder: Controlled Fe₂O₃ for ceramics, fillers, refractories

Industrial Powder: High tolerance impurities, used in cement, ferro-alloys, and refractory mixes

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

Supply Format: Export-ready, consistent micronized grades