OUR MINERALS

QUARTZ

Critical industrial mineral, valued for its high silica content, low impurities, and versatility. Mineastra supplies Quartz in Lumps, Grits, Powder, and HPQ (High-Purity Quartz), serving glass, ceramics, electronics, foundries, engineered stone, and construction industries. With partner mine capacity of 8,000–10,000 MT/month, Mineastra delivers consistent bulk supply of Quartz Lumps, Grits, and Powder for glass, ceramics, and industrial buyers.

RAW STONES

QUARTZ

LUMPS

White (Snow-White Grade)

Semi-white / off-white

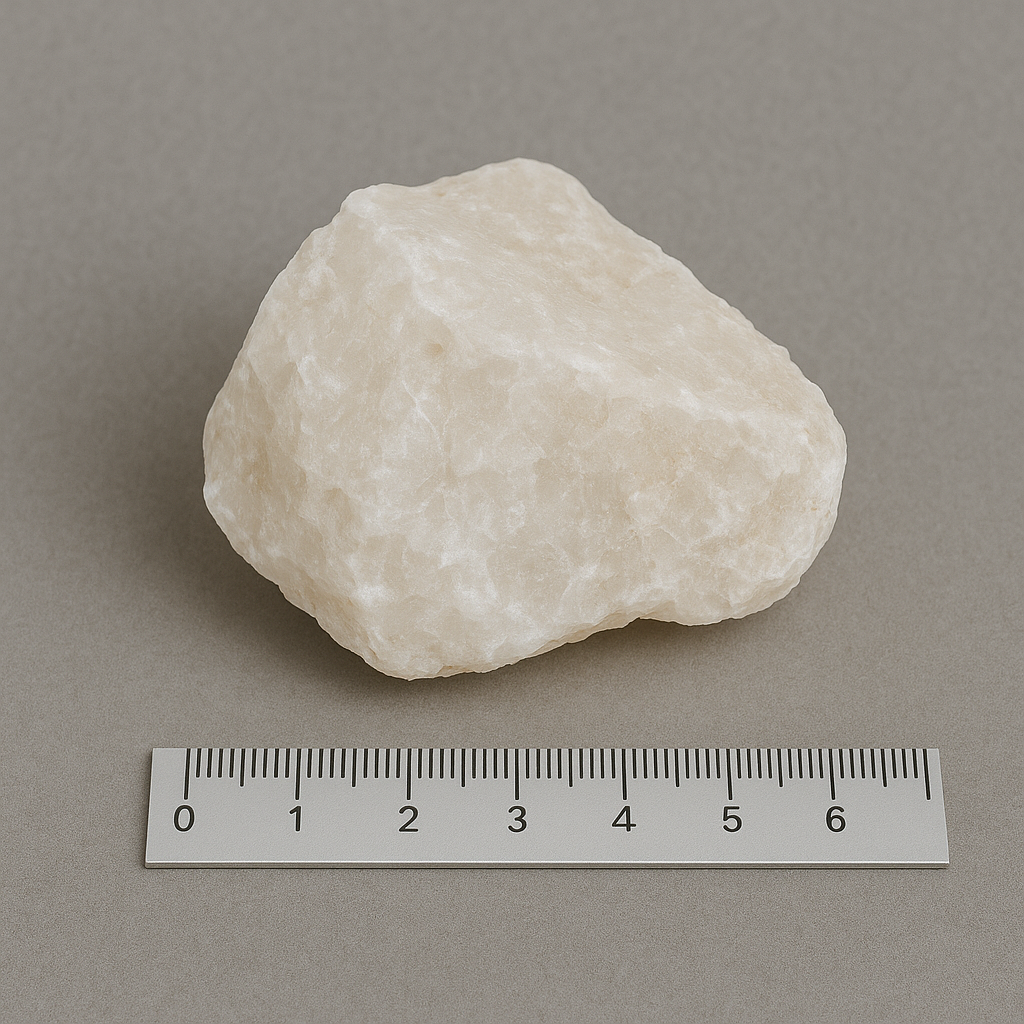

Snow White Quartz Lumps

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina): ≤ 0.3%

Fe₂O₃ (Iron Oxide): ≤ 0.02%

Moisture: < 0.1%

Whiteness: 97%

Color / Appearance: Brilliant, pure white

Applications:

High-grade glass manufacturing

Optical glass

Solar glass

Premium engineered stone (slabs & countertops)

High-purity ceramics

Industrial

Industrial Grade Quartz Lumps

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture: < 0.5%

Whiteness: 85%

Color / Appearance: White-grey, brownish patches

Applications:

Bulk cement production

Ferro-silicon alloying

Construction fillers

Refractory bricks

Chemical industries

Milky White

Milky White Quartz Lumps

SiO₂ (Silica): 98.5-99.5%

Al₂O₃ (Alumina): 0.3% – 0.7%

Fe₂O₃ (Iron Oxide): 0.03-0.05%

Moisture < 0.2%

Whiteness: 90% – 94%

Color / Appearance: Bright milky white, uniform, minimal patches

Applications:

Countertops & engineered stone (quartz surfaces)

Glass manufacturing (clear/colored glass)

High-end ceramics & sanitaryware

Foundry applications

Physical Specifications

Size Fractions (Screened & Graded): 25 – 50 mm, 50 – 100 mm, 100 – 150 mm, 150 – 250 mm, 250 mm

Density / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Manual handpicking, optical sorting, or mechanized screening

Impurity Control:

Low Fe₂O₃ for glass & ceramics

Strict selection for engineered stone

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

POWDER

PROCESSED

QUARTZ

Semi White Powder

Semi White Quartz Powder

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92% (slight cream)

Color / Appearance: Off-white / cream shade

Applications:

Container & regular glass

Sanitaryware ceramics

Refractories

Foundries (moulding sand)

Paints & coatings fillers

Snow-white Grits

Semi White Quartz Grits

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92% (slight cream)

Color / Appearance: Off-white / cream shade

Applications:

Container & regular glass

Sanitaryware ceramics

Refractories

Foundries (moulding sand)

Paints & coatings fillers

HPQ Quartz Crystal

Off White / Cream Quartz Lumps

SiO₂ (Silica): 98.5%

Al₂O₃ (Alumina): 1.0%

Fe₂O₃ (Iron Oxide): 0.08%

Moisture: < 0.3%

Whiteness: 92%

Color / Appearance: Slight cream / off-white

Applications:

Regular glass manufacturing

Sanitaryware ceramics

Foundries (moulding sand)

Paints & coatings fillers

Refractories

Physical Specifications

Size Fractions (Screened & Graded): 0.1 – 0.3 mm, 0.3 – 0.6 mm, 0.6 – 1.2 mm, 1.2 – 2.5 mm, 2.5 – 4.0 mm, 4.0 – 6.0 mm, 6.0 – 10 mm

Density / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Multi-stage crushing, sieving, and optional optical sorting for premium grades

Impurity Control:

Snow White: Ultra-low Fe₂O₃ (<0.02%) for solar, optical glass, engineered stone

Semi White: Balanced Fe₂O₃ levels, strict sizing for sanitaryware/ceramics

Industrial Mixed: Higher tolerance impurities, optimized for cement & metallurgical industries

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

MICRONISED

QUARTZ

GRITS

Snow White powder

Snow White Quartz Powder

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina) ≤ 0.3%

Fe₂O₃ (Iron Oxide) ≤ 0.02%

Moisture < 0.1%

Whiteness: 96 – 97% (ultra white)

Color / Appearance: Pure brilliant white, fine powder

Applications

Engineered stone & quartz slabs

Optical & solar glass

High-purity ceramics

Paints & coatings fillers

Plastics & polymers

Industrial Grits

Industrial Powder

Industrial Quartz Powder

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture < 0.5%

Whiteness: 80-85% (greyish)

Color / Appearance: White-grey, mixed tone powder

Applications

Bulk cement production

Construction fillers

Ferro-silicon alloying

Refractory bricks

Chemical industries

Physical Specifications

Particle Sizes (Micronized):

D50 = 45 µm, 38 µm, 25 µm, 20 µm, 10 µm, 5 µmDensity / Bulk Density: 1.55 – 1.65 g/cm³

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Sorting Method: Multi-stage crushing → ball mill/pulverizing → micronized sieving → air classification

Impurity Control:

Snow White Powder: Ultra-low Fe₂O₃ for engineered stone, solar glass, optical-grade uses

Semi White Powder: Controlled Fe₂O₃ for ceramics, fillers, refractories

Industrial Powder: High tolerance impurities, used in cement, ferro-alloys, and refractory mixes

Industrial Quartz Grits

SiO₂ (Silica): 97%

Al₂O₃ (Alumina): 1.5%

Fe₂O₃ (Iron Oxide): 0.15%

Moisture < 0.5%

Whiteness: 80 – 85% (greyish)

Color / Appearance: White-grey, mixed tone powder

Applications

Bulk cement production

Construction fillers

Ferro-silicon alloying

Refractory bricks

Chemical industries

Packaging & Supply

Packaging Options:

Jumbo bags (1 MT)

HDPE woven bags (50 kg)

Loose container loading

Container Capacity: ~25 MT / 20 ft container.

Supply Format: Export-ready, consistent micronized grades

HIGH PURITY (HPQ)

High-Purity Quartz (HPQ) is the critical raw material for electronics, semiconductors, solar, and optics. Unlike industrial quartz used in glass and ceramics, HPQ requires naturally formed quartz crystals with ultra-low impurities and low electrical conductivity (EC).

Mineastra sources crystalline quartz feedstock from select belts in India and supplies it to global HPQ processors who refine it into specialty applications. With identified partner mines having enough supply capacity, we are aiming to lead the global silicon supply.

Semi-white Grits

HPQ Crushed Lumps / Chips

SPECIFICATIONS

SiO₂ (Silica) ≥ 99.95% – 99.99%

Al₂O₃ (Alumina) ≤ 50 ppm (0.005%)

Fe₂O₃ (Iron Oxide) ≤ 20 ppm (0.002%)

TiO₂ (Titania) ≤ 20 ppm (0.002%)

K₂O + Na₂O (Alkalis) ≤ 20 ppm

CaO + MgO ≤ 30 ppm

Moisture < 0.05%

Whiteness > 98% (clear, transparent to translucent)

Color / Appearance: Transparent to translucent crystal lumps, very low inclusions, chips are angular/cubic with clean fracture

Trace Elements (B, Li, etc.): Controlled below detection limits for semiconductor-grade supply

Physical Specifications

Lump Sizes: 20 – 100 mm, 50 – 150 mm, 100 – 250 mm

Chip Sizes (crushed/crystal chips): 5 – 20 mm, 10 – 30 mm, 20 – 50 mm

Density / Bulk Density: 2.65 g/cm³ (true quartz density, very consistent)

Hardness (Mohs): 7

Thermal Stability: Melting point ~1710°C

Electrical Properties: Very high dielectric strength, extremely low electrical conductivity (critical for semiconductor uses)

Sorting & Grading

Sorting Method:

Manual handpicking + optical sorting for transparency and low inclusion

Acid leaching (HCl, HF) to reduce Fe, Al, Ti to ppm levels

High magnetic separation for trace Fe removal

Washing, calcination, and controlled crushing for chip production

Applications

Semiconductors & Electronics:

Crucibles for pulling monocrystalline silicon (Czochralski process)

Quartz tubes & rods for semiconductor furnaces

Wafer carriers, diffusion tubes

Solar PV Industry:

Crucibles & quartz glass for polysilicon melting

Quartz tubes for solar furnaces and photovoltaic production

Optics & Fiber:

High-transparency glass for precision optics

Optical fibers, lenses, prisms

Advanced Ceramics & Specialty Uses:

High-performance ceramics, quartz ware

Aerospace, defense, and laboratory-grade quartz products

Packaging & Supply

Packaging Options:

Acid-washed PE lined jumbo bags (1 MT)

Smaller HDPE bags (25 / 50 kg) for chips

Wooden crates for crystal lumps (to prevent contamination and mechanical damage)

Container Capacity: ~25 MT / 20 ft container (bulk bags), lower for premium crystal crates (to avoid breakage)

Supply Format: Controlled supply, batch-certified with ICP-MS / XRF analysis reports, traceability per lot

Grades of HPQ:

Solar Grade HPQ: For photovoltaic glass crucibles, solar tubes

Semiconductor Grade HPQ: For silicon crucibles, silicon wafer production

Optical Grade HPQ: For high-precision lenses, fiber optics

QUARTZ

Snow White Quartz Grits

SiO₂ (Silica): 99.5%

Al₂O₃ (Alumina): ≤ 0.3%

Fe₂O₃ (Iron Oxide): ≤ 0.02%

Moisture: < 0.1%

Whiteness: 97%

Color / Appearance: Brilliant, pure white

Applications:

High-grade glass manufacturing

Optical glass

Solar glass

Premium engineered stone (slabs & countertops)

High-purity ceramics

FELDSPAR

Feldspar is an essential mineral acting as a fluxing agent. Mineastra offers Soda Feldspar and Potash Feldspar in Lumps, Grits, and Powder. Backed by 2,500–3,500 MT/month partner mine capacity, Mineastra ensures reliable Soda, Potash, and Mixed Feldspar supply for ceramics, glazes, and glass industries.

FELDSPAR

LUMPS

Potash Feldspar

Potash Feldspar Lumps (K-Feldspar)

SiO₂ (Silica):68 – 70%

Al₂O₃ (Alumina): 17 – 19%

K₂O (Potassium Oxide): 10 – 12%

Na₂O (Sodium Oxide): 2 – 4%

Fe₂O₃ (Iron Oxide) ≤ 0.05% (premium)

CaO + MgO ≤ 0.5%

Moisture < 0.5%'

Whiteness (after firing: )90 – 92% (brilliant white)

Whiteness (after firing): Pinkish to cream, blocky lumps

Applications

Ceramics & sanitaryware

Vitrified & porcelain tiles

Glass manufacturing (specialty glass)

Glazes & frits

Soda Feldspar

Soda Feldspar Lumps (Na-Feldspar)

SiO₂ (Silica): 68 – 70%

Al₂O₃ (Alumina): 18 – 20%

K₂O (Potassium Oxide): 2 – 4%

Na₂O (Sodium Oxide): 7 – 9%

Fe₂O₃ (Iron Oxide) ≤ 0.08%

CaO + MgO ≤ 0.7%

Moisture < 0.5%

Whiteness (after firing): 88 – 90% (off-white)

Whiteness (after firing): Off-white to bluish, blocky lumps

Applications

Container glass & flat glass

Ceramic tiles & sanitaryware

Electrical insulators

Glazes & frits

Physical Specifications

Size Fractions (Screened & Graded):

25 – 50 mm, 50 – 100 mm, 100 – 150 mm, 150 – 250 mm, 250 mm+Density / Bulk Density: 2.55 – 2.62 g/cm³

Hardness (Mohs): 6 – 6.5

Thermal Expansion: ~5 × 10⁻⁶ /°C

Sorting & Grading

Sorting Method: Manual handpicking, mechanized screening, optical color sorting (for premium potash/soda grades)

Impurity Control:

Potash: Low Fe₂O₃ for ceramics, sanitaryware, and premium glass

Soda: Strict control of Fe & Ti for glass industry demand

Industrial Mixed: Higher tolerance impurities, used in bulk/low-cost ceramics and refractories

Industrial / mixed color grade

Industrial / Mixed Color Feldspar Lumps

SiO₂ (Silica): 65 – 68%

Al₂O₃ (Alumina): 17 – 19%

K₂O (Potassium Oxide): 3 – 5%

Na₂O (Sodium Oxide): 4 – 6%

Fe₂O₃ (Iron Oxide) ≤ 0.15%

CaO + MgO ≤ 1.0%

Moisture < 0.5%

Whiteness (after firing): 75 – 85% (mixed tones, grey/brown specks)

Whiteness (after firing): Mixed white-grey with visible inclusions

Applications

Bulk ceramics (low-grade tiles, bricks)

Construction ceramics & fillers

Refractories

Low-grade glass

40–150 mm

RAW, ASSORTED STONES

BROKEN DOWN, PROCESSED

FELDSPAR

GRITS

Packaging & Supply

Packaging Options:

Jumbo Bags: 1 MT with liner

HDPE Woven Bags: 50 kg

Loose container loading for bulk buyers

Container Capacity: ~25 MT / 20 ft container

Potash Grits

Potash Feldspar Grits (K-Feldspar)

SiO₂ (Silica): 68 – 70%

Al₂O₃ (Alumina): 17 – 19%

K₂O (Potassium Oxide): 10 – 12%

Na₂O (Sodium Oxide): 2 – 4%

Fe₂O₃ (Iron Oxide): ≤ 0.05% (premium)

CaO + MgO: ≤ 0.5%

Moisture: < 0.3%

Whiteness (after firing): 90 – 92% (bright white)

Color / Appearance: Pinkish-white, angular grit sizes

Applications

Porcelain & vitrified tiles'

Sanitaryware ceramics

Glazes & frits

Specialty glass

Physical Specifications

Size Fractions (Screened & Graded):

0.1 – 0.3 mm, 0.3 – 0.6 mm, 0.6 – 1.2 mm, 1.2 – 2.5 mm, 2.5 – 4.0 mm, 4.0 – 6.0 mm, 6.0 – 10 mmDensity / Bulk Density: 2.55 – 2.62 g/cm³

Hardness (Mohs): 6 – 6.5

Thermal Expansion: ~5 × 10⁻⁶ /°C

Sorting & Grading

Sorting Method: Manual handpicking, optical sorting, or mechanized screening.

Sorting Method: Multi-stage crushing → screening → optical color sorting (premium grades)

Impurity Control:

Potash: Low Fe₂O₃ (<0.05%) for ceramics & glazes

Soda: Strict Fe/Ti removal for glass manufacturing

Soda Grits

Soda Feldspar Grits (Na-Feldspar)

SiO₂ (Silica): 68 – 70%

Al₂O₃ (Alumina): 18 – 20%

K₂O (Potassium Oxide): 2 – 4%

Na₂O (Sodium Oxide): 7 – 9%

Fe₂O₃ (Iron Oxide): ≤ 0.08%

CaO + MgO: ≤ 0.7%

Moisture: < 0.3%

Whiteness (after firing): 88 – 90% (off-white / bluish)

Color / Appearance: Off-white / bluish, angular grit

Applications

Container & flat glass

Ceramic tiles & sanitaryware

Electrical insulators

Glazes & frits

Packaging & Supply

Packaging Options:

Jumbo Bags: 1 MT with liner

HDPE Woven Bags: 50 kg

Loose container loading

Container Capacity: ~25 MT / 20 ft container

Supply Format: Consistent export-ready batches, screened & graded

FINE, MICRONISED

Potash

Potash Feldspar Powder (K-Feldspar)

SiO₂ (Silica): 68 – 70%

Al₂O₃ (Alumina): 17 – 19%

K₂O (Potassium Oxide): 10 – 12%

Na₂O (Sodium Oxide): 2 – 4%

Fe₂O₃ (Iron Oxide) ≤ 0.05% (premium)

CaO + MgO ≤ 0.5%

Moisture < 0.3%

Whiteness (after firing): 90 – 92% (bright white)

Color / Appearance: Fine, pinkish-to-cream powder

Applications:

Porcelain & vitrified tiles

Sanitaryware ceramics

Glazes & frits

Specialty glass

Physical Specifications

Particle Sizes (Micronized): D50 = 45 µm, 38 µm, 25 µm, 20 µm, 10 µm, 5 µm

Density / Bulk Density: 2.55 – 2.62 g/cm³

Hardness (Mohs): 6 – 6.5

Thermal Expansion: ~5 × 10⁻⁶ /°C

Sorting & Grading

Processing Method: Crushing → Ball mill / Pulverizing → Air separation → Micronized sieving

Impurity Control:

Potash: Ultra-low Fe₂O₃ for premium ceramics & porcelain

Soda: Fe/Ti controlled for glass and glaze industries

Soda

Soda Feldspar Powder (Na-Feldspar)

SiO₂ (Silica): 68 – 70%

Al₂O₃ (Alumina): 18 – 20%

K₂O (Potassium Oxide): 2 – 4%

Na₂O (Sodium Oxide): 7 – 9%

Fe₂O₃ (Iron Oxide) ≤ 0.08%

CaO + MgO ≤ 0.7%

Moisture < 0.3%

Whiteness (after firing): 88 – 90% (off-white / bluish)

Color / Appearance: Fine, off-white-to-bluish powder

Applications:

Container & flat glass

Ceramic tiles & sanitaryware

Electrical insulators

Glazes & frits

Packaging & Supply

Packaging Options:

HDPE Woven Bags: 25 kg / 50 kg

Jumbo Bags: 1 MT with liner

Custom bulk packaging for industrial users

Container Capacity: ~25 MT / 20 ft container

Supply Format: Export-ready, micronized powder, batch-certified

FELDSPAR

POWDER

QUARTZITE

LUMPS

Construction/Crushed

Quartzite Lumps – Construction / Crushed

SiO₂ (Silica): 95 – 97%

Al₂O₃ (Alumina): 1.0 – 1.5%

Fe₂O₃ (Iron Oxide): 0.5 – 1.0%

CaO + MgO ≤ 1.5%

Moisture < 0.5%

Whiteness / Color: Greyish to off-white, coarse texture

Appearance: Hard, angular crushed stone

Applications

Road construction aggregate

Railway ballast

Concrete & asphalt mixes

Building stone

General civil works

Physical Specifications

Size Fractions:

Construction/Crushed: 20 – 40 mm, 40 – 80 mm, 80 – 150 mm, 150 mm+

Refractory/Ferroalloy: 25 – 50 mm, 50 – 100 mm, 100 – 200 mm

Density / Bulk Density: 2.6 – 2.65 g/cm³

Hardness (Mohs): 7+ (very high abrasion resistance)

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Processing Method:

Construction grade: Mechanized crushing, screening, washing

Ferroalloy/Refractory grade: Selective quarrying, hand sorting for low Fe and consistent chemistry

Impurity Control:

Construction: Tolerant to Fe and Al impurities

Ferroalloy/Refractory: Strict Fe₂O₃ < 0.3% for furnace-grade silica

QUARTZITE

POWDER

Quartzite Powder

Quartzite Powder – Construction Grade

SiO₂ (Silica): 95 – 97%

Al₂O₃ (Alumina): 1.0 – 1.5%

Fe₂O₃ (Iron Oxide): 0.5 – 1.0%

CaO + MgO ≤ 1.5%

Moisture < 0.5%

Whiteness / Color: Greyish to off-white, coarse finish

Appearance: Coarse to medium-fine ground powder

Applications

Cement & concrete additives

Asphalt fillers

Ceramic floor tiles

Paints & construction fillers

Physical Specifications

Particle Sizes:

Construction Grade: D50 = 150 µm, 75 µm, 45 µm

Refractory/Ferroalloy Grade: D50 = 75 µm, 45 µm, 25 µm, 10 µm (micronized)

Density / Bulk Density: 2.6 – 2.65 g/cm³

Hardness (Mohs): 7+

Thermal Stability: Melting point ~1710°C

Sorting & Grading

Processing Method:

Crushing → Grinding (hammer mill / ball mill) → Air classification → Micronized sieving

Impurity Control:

Construction Grade: Tolerant to Fe₂O₃ up to 1%

Refractory Grade: Fe₂O₃ ≤ 0.3%, strict control of Al₂O₃ and alkalis, acid washing possible for premium batches

QUARTZITE

Quartzite is valued for its strength, high silica content, and heat resistance, making it ideal for, We can be supplying 2,000–3,000 MT/month, Mineastra provides dependable Quartzite for ferro-alloys, refractories, and construction.

25–200 mm

RAW STONES, BOULDERS

Refractory / Ferroalloy

Quartzite Lumps – Refractory / Ferroalloy

SiO₂ (Silica): 97.5 – 99%

Al₂O₃ (Alumina) ≤ 0.8%

Fe₂O₃ (Iron Oxide) ≤ 0.3%

CaO + MgO ≤ 0.5%

Moisture < 0.3%

Whiteness / Color

Whiteness / Color: Off-white to light grey, clean fracture

Appearance: Dense, blocky lumps with minimal inclusions

Applications

Ferro-silicon & silicon manganese alloys

Ferroalloy furnaces

Flux in metallurgical processes

High-grade construction aggregates

Packaging & Supply

Packaging Options:

Loose bulk loading (tipper trucks, bulk vessels)

Jumbo Bags (1 MT) for furnace-grade export

Container Capacity: ~25 MT / 20 ft container (bagged)

Supply Format: Bulk supply for construction; certified, graded lots for refractory/metallurgical use

PROCESSED

Quartzite Sand

Quartzite Powder – Refractory / Ferroalloy Grade

SiO₂ (Silica): 97.5 – 99%

Al₂O₃ (Alumina)≤ 0.8%

Fe₂O₃ (Iron Oxide)

CaO + MgO ≤ 0.3%

Moisture ≤ 0.5%

Whiteness / Color: < 0.3%; Off-white to light grey, clean powder

Appearance: Fine micronized powder, consistent particle size

Applications

Ferro-silicon alloying flux

Silicon manganese production

Refractory bricks & castables

Foundry moulds

Metallurgical fluxes

Packaging & Supply

Packaging Options:

HDPE Woven Bags: 25 / 50 kg

Jumbo Bags: 1 MT with liner

Bulk tanker loading (for construction fillers)

Container Capacity: ~25 MT / 20 ft container

Supply Format: Regular bulk supply for construction; certified lots for refractory/metallurgical industries